2026 How to Choose the Right Geotex Membrane for Your Project?

Choosing the right Geotex Membrane for your project can be daunting. Experts often discuss the importance of selection. John Smith, a veteran in the geotextile industry, once said, “The right membrane can make or break your project’s success.” His words ring true as many face challenges in this area.

Geotex Membrane is crucial for various applications. Their roles include drainage, erosion control, and filtration. Selecting the appropriate type requires understanding project needs. It’s not just about picking any membrane. It often involves asking hard questions about performance and durability.

Some projects fail due to poor choices in geotextiles. A common mistake is underestimating environmental conditions. Membranes must withstand different pressures and temperatures. Evaluate specifics for your site. Attention to detail matters. The right Geotex Membrane can provide lasting benefits, yet finding it requires effort and deeper insight.

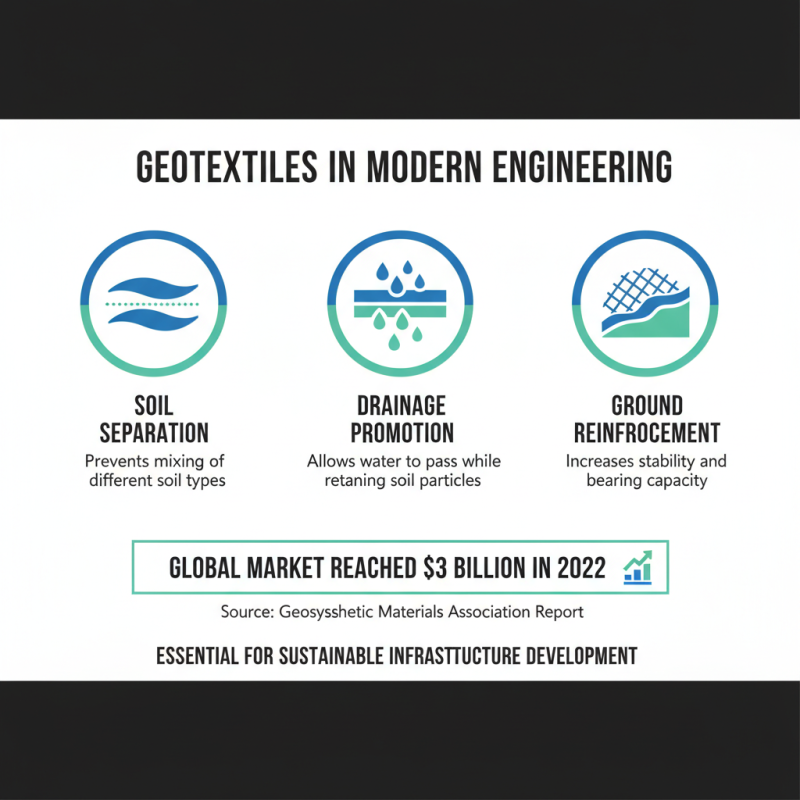

Understanding Geotextiles: Definition and Functions

Geotextiles play a crucial role in modern engineering and construction projects. These materials, made from synthetic fibers, serve various functions. They can separate soil layers, promote drainage, and reinforce ground stability. According to a report by the Geosynthetic Materials Association, the global market for geotextiles reached over $3 billion in 2022. This growth highlights their importance in infrastructure development.

When selecting a geotextile, consider its function. Some geotextiles are designed for filtration, while others focus on drainage or stabilization. Choosing the wrong type may lead to project failure. Inadequate filtration might cause soil erosion. Insufficient drainage could lead to water pooling, affecting stability. It's essential to analyze your project needs carefully.

Tip: Always assess soil properties before making a choice. Understanding soil composition can guide your selection. Different projects may require specific types of geotextiles. Don't rely on one-size-fits-all solutions; customization is key.

Furthermore, remember that not all geotextiles are equal. Some may degrade faster under UV exposure, impacting longevity. Proper testing and quality inspection should not be overlooked. A cheap option might cost more in the long run due to premature failure. It's vital to weigh cost savings against durability and performance for successful project outcomes.

Types of Geotext Membranes: Comparing Options

Choosing the right geotext membrane involves understanding various options. Geotextiles are categorized into woven, non-woven, and knitted types. Each type meets different project needs. For example, woven geotextiles provide excellent tensile strength. They are ideal for reinforcement. Non-woven geotextiles offer superior filtration. They work well for drainage applications.

Industry reports indicate that the global geotextile market is expected to grow by 10% annually. This growth shows the increasing demand for these materials in civil engineering projects. Many projects benefit from the durability and effectiveness of geotextiles during construction and soil stabilization. Yet, the selection often relies on specific project criteria, such as soil type and environmental conditions.

Some project managers overlook the importance of proper selection. They may choose a membrane based solely on cost. A wrong choice can lead to increased expenses. It may cause premature failures. Awareness of the technical properties is crucial. For instance, a woven membrane might not perform well in waterlogged areas. Evaluating the specific needs of your project ensures better long-term outcomes. Make thoughtful decisions to avoid common pitfalls.

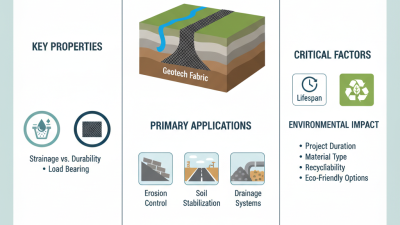

Factors to Consider When Selecting a Geotex Membrane

Choosing the right geotextile membrane for your project involves several key factors. First, understand the primary function of the membrane. Is it for filtration, separation, or reinforcement? Each goal requires a different type of material. Consider the soil characteristics, too. Cohesive soils and granular soils interact differently with geotextiles. This will impact your choice significantly.

Tips: Always assess the environmental conditions. UV exposure, moisture, and temperature can affect durability. A membrane that works well in one climate may fail in another. Additionally, think about project duration. Temporary projects might not need the same quality as permanent structures.

Think about installation ease. Some membranes are more challenging to handle than others. Consider labor costs and project timelines. A complicated installation might lead to errors and delays. Each of these details can influence the overall success of your project. Reflect on your choices carefully before finalizing them.

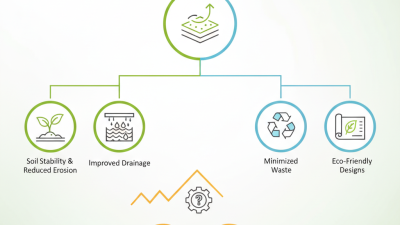

Applications of Geotex Membranes in Various Projects

Geotex membranes are vital in various projects, offering significant benefits. They play a crucial role in erosion control on slopes. When properly installed, they enhance soil stability. This is particularly important in civil engineering projects near water bodies.

These membranes are also useful in landfill systems. They help manage leachate and support the integrity of the barrier system. Additionally, they can be integral in road construction. They separate layers, preventing mixing and ensuring durability. However, selecting the wrong type can lead to failures.

In agricultural settings, geotex membranes assist in drainage. They improve water management, especially in crop fields. Still, it’s essential to assess soil conditions before installation. In this complexity, reevaluations and adjustments can be necessary. Investing time here can make a significant difference.

2026 How to Choose the Right Geotex Membrane for Your Project?

| Project Type | Geotex Membrane Type | Primary Applications | Key Benefits |

|---|---|---|---|

| Road Construction | Non-woven Geotextile | Soil stabilization, Subgrade separation | Improved load distribution, Reduced maintenance costs |

| Landfills | Woven Geotextile | Leachate collection, Barrier protection | High tensile strength, Durability against chemical exposure |

| Erosion Control | Biodegradable Geotextile | Reinforcing soil on slopes, Promoting vegetation growth | Eco-friendly, Integrated decomposition over time |

| Drainage Systems | Permeable Geotextile | Water filtration, Groundwater management | Allows water flow while retaining soil particles |

| Green Roofs | Geocomposite | Vegetative roofing systems, Moisture retention | Enhanced insulation, Aesthetic benefits |

Best Practices for Installation and Maintenance of Geotex Membranes

Proper installation and maintenance of geotextile membranes are crucial for project success. According to industry reports, improperly installed membranes can reduce their effectiveness by up to 30%. This loss can lead to severe project delays and increased costs. Therefore, ensuring the correct installation process is vital. Adequate soil preparation is key. The surface must be free of sharp objects and irregularities. Membranes should be laid out flat, without wrinkles or folds to avoid water trapping.

Regular inspections are essential in maintenance. A study highlighted that 25% of failures occurred due to neglecting routine checks. Identifying issues early can save considerable resources. Employing a suitable cover over the membranes is advisable. This practice protects them from UV damage and mechanical stress. Awareness and training of personnel handling these membranes cannot be understated. Mistakes often arise from a lack of understanding.

Finally, consider environmental factors. Moisture content, temperature variations, and soil acidity all influence a geotextile's longevity. Reflecting on these aspects can lead to better project outcomes. In the end, creating a checklist for installation and maintenance ensures all necessary steps are covered. This proactive approach can enhance performance and extend the lifespan of geotextile membranes.

Related Posts

-

How to Choose the Right Woven Geofabric for Your Project?

-

The Ultimate Guide to Understanding Geotextile Mats and Their Impact on Environmental Protection

-

Exploring Innovations in Gsm Geotextile at the 2025 China Import and Export Fair

-

Top 10 Geotextile Gsm Types You Need to Know?

-

Geotech Fabric Tips for Choosing the Best Material?

-

2026 Best Geotech Fabric Options for Sustainable Construction Solutions?

-

Phone

-

E-mail

-

Whatsapp

-

Top