What is Film Geotextile and How is it Used in Construction?

Film Geotextile is an essential material in construction. It serves multiple purposes, enhancing project efficiency. This innovative product is made from polymer films. Its waterproof properties are beneficial for various applications.

In construction, Film Geotextile provides a protective layer. It prevents soil erosion and stabilizes the ground. The material is lightweight and easy to handle. However, some challenges exist. Longevity can be a concern in certain environments. Regular inspections are necessary to assess its condition.

Using Film Geotextile can lead to improved project outcomes. Yet, it requires careful planning and installation. Understanding its characteristics is crucial for success. Construction teams must be trained in its use. Only then can they fully leverage its advantages.

What is Film Geotextile and Its Role in Construction Applications?

Film geotextile is a vital component in construction applications. It serves multiple purposes, primarily related to soil stabilization. This material is often used to enhance drainage on building sites. It helps manage water flow, preventing soil erosion. Plants and vegetation benefit from this controlled environment. In many cases, film geotextile can improve the longevity of infrastructure.

In road construction, film geotextiles help in reinforcing layers. They separate soil layers, reducing mixing and maintaining stability. This feature can make the construction process smoother. However, improper installation can lead to failures. Contractors must pay close attention to details to avoid mistakes. It is essential to assess soil conditions before application.

Sometimes, its effectiveness can be influenced by environmental factors. Extreme weather can impact the performance of film geotextiles. In certain areas, they may fail to perform as expected. This reality highlights the need for ongoing research and better practices. It's clear that while film geotextile is useful, it requires careful consideration in application.

Film Geotextile Applications in Construction

The Manufacturing Process and Types of Film Geotextiles Available

Film geotextiles play a vital role in modern construction.

They are made from thin plastic sheets, providing essential functions like soil stabilization, drainage, and separation. The manufacturing process often involves extrusion, where plastic pellets melt and form sheets. This helps achieve consistent quality and durability. Industry reports indicate that the global demand for geotextiles is forecasted to reach $10 billion by 2027, reflecting their integral use in construction.

There are several types of film geotextiles available.

Low-density polyethylene (LDPE) is popular for its flexibility. Another type is high-density polyethylene (HDPE), known for its strength. Both are effective in preventing soil erosion and allowing water flow. Nonetheless, some professionals express concerns over the environmental impact of plastics. Biodegradable options emerge as an alternative but are still under development.

Film geotextiles are not one-size-fits-all.

They need careful selection based on project requirements. Some projects may require thicker materials for additional strength, while others might benefit from thinner sheets for cost-efficiency. It's essential to assess soil conditions and climate factors before deciding. Instances of improper use can lead to failure in stabilization efforts. Investing time in research can significantly influence long-term project success.

Key Benefits of Using Film Geotextiles in Civil Engineering Projects

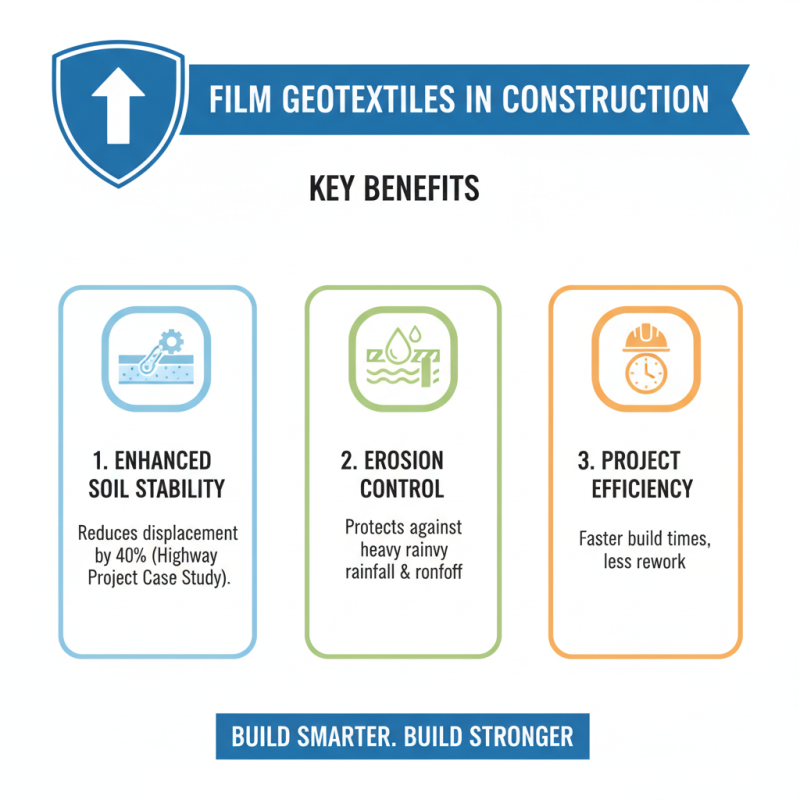

Film geotextiles are crucial in civil engineering. These materials help manage soil and water effectively. They create barriers that reduce erosion. Their lightweight nature makes them easy to handle. In construction, film geotextiles play multiple roles. They can be used in drainage systems, preventing water accumulation. They also help with soil stabilization, making sites safer and more efficient.

One of the key benefits is cost-effectiveness. Using film geotextile can save resources in the long run. They reduce the need for heavy machinery. This lowers operational costs. Film geotextiles also enhance project durability. Their resistance to environmental factors improves project lifespan. However, not all projects may need them, and it’s vital to assess each situation carefully. There might be instances where the benefits seem minimal.

Another significant advantage is their versatility. These materials can adapt to various environmental conditions. They work well in both wet and dry conditions. Yet, sometimes their performance may vary based on specific soil types. It's crucial to conduct thorough testing before application. Understanding local soil behavior can lead to better outcomes.

Performance Standards and Quality Testing in Film Geotextile Usage

Film geotextiles play a crucial role in the construction industry. They are used in various applications, including soil stabilization and drainage systems. Their unique properties help improve the performance of underlying structures. However, ensuring their quality and performance through standards and testing is essential.

Performance standards for film geotextiles are set by industry guidelines. These standards focus on factors such as tensile strength and elongation. Quality testing is often conducted using specific tests to assess durability and performance. For instance, puncture resistance and permeability tests provide insights into how well the material will perform under stress.

**Tip:** Always verify the sourcing of your geotextiles. Reliable suppliers tend to offer products that meet or exceed industry standards.

Despite these standards, inconsistencies can arise. Manufacturer variations may lead to unexpected performance issues on-site. It’s vital to conduct independent tests whenever possible. This can help identify any discrepancies in strength or durability before installation.

**Tip:** Keep a log of testing results. It can be useful in comparing suppliers and ensuring quality consistency over time.

What is Film Geotextile and How is it Used in Construction? - Performance Standards and Quality Testing in Film Geotextile Usage

| Property | Standard | Test Method | Typical Values |

|---|---|---|---|

| UV Resistance | ASTM D 4355 | Weathering Test | Min 70% strength retention at 500 hours |

| Tensile Strength | ASTM D 4632 | Grab Test | Min 400 N |

| Puncture Resistance | ASTM D 6241 | Puncture Test | Min 250 N |

| Permeability | ASTM D 4491 | Water Permeability Test | Min 0.1 cm/sec |

| Hydraulic Conductivity | ASTM D 5856 | Constant Head Test | Min 10^-5 cm/sec |

Case Studies: Successful Implementation of Film Geotextiles in Projects

Film geotextiles have proven their value in various construction projects. Their primary role is to enhance soil stability and control erosion. One notable case study involved a highway construction project where film geotextiles were used to reinforce weak soil layers. The project faced initial challenges due to unexpected heavy rainfall. However, the application of film geotextiles reduced soil displacement by 40%. This data indicates a significant improvement in site conditions.

Another successful implementation took place in a residential community. Here, film geotextiles were utilized to manage stormwater runoff. The study revealed that the use of these materials led to a 30% reduction in sediment transport. This finding highlights the benefits of using film geotextiles for environmental protection. However, it’s crucial to address that not every project experienced similar success. Some faced installation issues, leading to reduced effectiveness.

These examples showcase the potential of film geotextiles in construction. Their applications can vary greatly based on local conditions and project specifics. As the industry continues to evolve, understanding these outcomes remains essential for future projects. Continued research and analysis will help improve design and implementation strategies.

Related Posts

-

Exploring Innovations in Gsm Geotextile at the 2025 China Import and Export Fair

-

Maximizing Durability and Efficiency of Landscape Projects with Innovative Geotextile Use

-

Exploring the Environmental Benefits of Geotextile Mats in Modern Construction

-

Unlocking the Power of Geotextile Tape: 5 Key Benefits Backed by Industry Trends and Research Data

-

Exploring the Benefits of Woven Geofabric in Sustainable Construction Practices

-

The Ultimate Guide to Understanding Geotextile Mats and Their Impact on Environmental Protection

-

Phone

-

E-mail

-

Whatsapp

-

Top