What is Geotextile Tape and How is it Used in Construction?

Geotextile Tape is an essential material in modern construction. It provides strength and stability to various projects. Often, it is used to secure geotextiles in place, ensuring soil retention and preventing erosion.

In construction, the application of Geotextile Tape helps in drainage and filtration. Professionals appreciate its durable nature. However, there are challenges to consider. Proper adhesion is critical for effectiveness, and improper use can lead to project failures.

Geotextile Tape is versatile but requires careful handling. It can simplify complex tasks. Yet, spontaneous application may not yield the best results. Understanding its properties ensures optimal use. With ongoing advancements, the potential of Geotextile Tape continues to expand, offering new possibilities in construction.

What is Geotextile Tape?

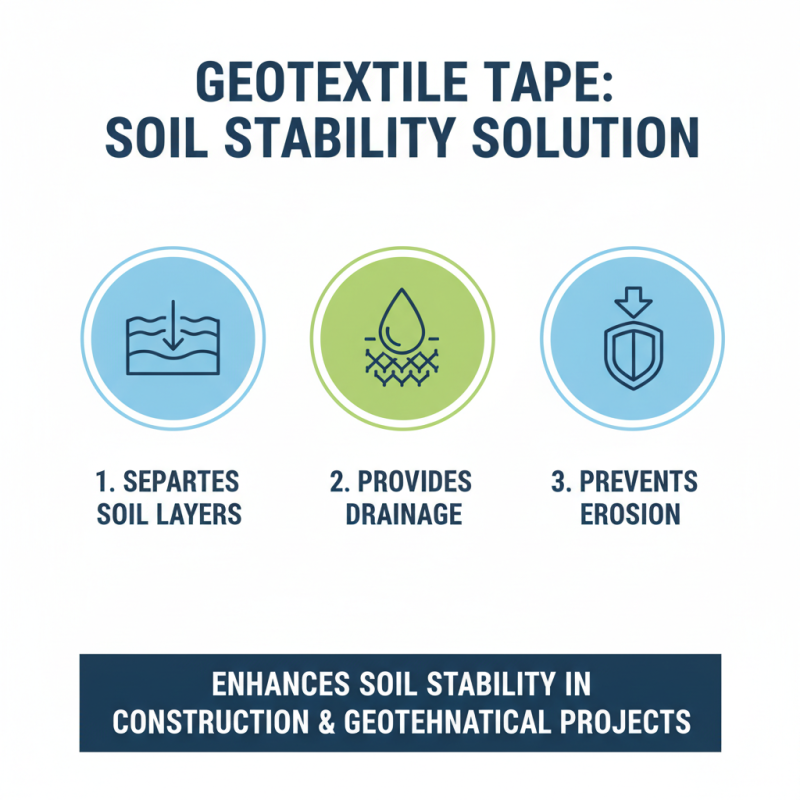

Geotextile tape is an essential tool in the construction industry. It’s made of porous materials, specifically designed to enhance soil stability. The tape works by separating different layers of soil, providing drainage while preventing erosion. It's commonly used in geotechnical engineering projects.

In many cases, geotextile tape is applied to reinforce embankments and roadways. When properly installed, it helps improve load-bearing capacity. However, improper use can lead to failures, like soil displacement. It's critical to ensure proper placement and tension. Users often overlook these details, leading to costly mistakes.

Moreover, the longevity of geotextile tape depends on environmental conditions. Exposure to UV rays can degrade the material over time. Users must assess their project’s specific needs, including soil types and weather conditions. Ignoring these factors can lead to premature deterioration and ineffective barriers.

Key Properties of Geotextile Tape in Construction

Geotextile tape is a versatile material used in construction. Its key properties make it ideal for various applications. This tape primarily offers strength and durability. It can withstand significant tension, making it essential for ground stabilization.

The adhesive quality is another crucial property. It bonds firmly with different surfaces, ensuring a secure hold. This property is beneficial for securing geotextiles to itself or to other materials. It's important to apply the tape on clean, dry surfaces for best results.

Tips: Always test the tape in a small area first. This helps avoid issues with bonding. Pay attention to temperature conditions; extreme heat or cold can affect performance.

Water resistance is another notable feature. It protects against moisture infiltration, which can compromise the integrity of construction projects. However, improper application can lead to water damage. Be mindful to seal edges properly while applying the tape.

When using geotextile tape, consider its environmental impact. Ensure that the materials you choose are sustainable. This is crucial for long-term project success. Reflection on application techniques is vital to enhance efficiency and effectiveness in future projects.

Common Applications of Geotextile Tape in Building Projects

Geotextile tape is becoming essential in modern construction. Its primary role is to reinforce soil and improve stability. This tape is made from synthetic materials, offering strength and durability. It is often used for drainage, separation, and erosion control in various building projects.

One common application of geotextile tape is in road construction. It helps prevent soil contamination from surrounding materials. Engineers often rely on it for effective drainage systems. In retaining walls, the tape provides support while allowing water to flow freely. Improper installation, however, can lead to water buildup behind the walls.

Another significant use is in landscaping. It stabilizes soil in erosion-prone areas. Builders implement it around pavements and slopes. The results can be impressive, but sometimes the tape fails. Misalignment or wrong material choice can diminish its benefits. Proper attention to detail is vital for optimal performance.

Installation Techniques for Effective Use of Geotextile Tape

Geotextile tape is increasingly popular in construction. It provides essential support for soil stabilization and erosion control. Effective use requires specific installation techniques. The right method ensures optimal performance, enhancing durability.

One key technique is surface preparation. Before applying the tape, the surface must be clean and dry. This prevents debonding. A study from the American Society of Civil Engineers found that improper preparation leads to a 30% reduction in effectiveness. Positioning the tape accurately is crucial. It should overlap at joints and seams, ensuring no gaps. Each layer reinforces the system.

Another important step is applying pressure. Sufficient pressure must be applied to activate the adhesive properly. A report from the International Geosynthetics Society highlighted that inadequate pressure can lead to premature failure. It’s also essential to monitor environmental conditions. High humidity can affect adhesion. Construction teams sometimes overlook these details. This can result in costly repairs and delays. Each project requires careful attention to these installation techniques for successful outcomes.

Benefits and Limitations of Using Geotextile Tape in Construction

Geotextile tape is increasingly used in construction. It provides essential benefits, but has limitations too. A key advantage is its ability to enhance soil stability. According to a report by the Geosynthetic Research Institute, projects using geotextiles show a 30% reduction in settlement issues. This can significantly lower maintenance costs.

However, geotextile tape is not without its drawbacks. It can be prone to UV degradation. If not protected, the tape may lose its effectiveness over time. Also, proper installation is critical. Misaligned tape can compromise its function. A study found that improper installation led to 40% of geotextile failures.

Tips: Always check for UV protection when selecting geotextile tape. Consider local environmental conditions. Regular inspections can identify early signs of degradation. Proper training for installation crews is vital. This ensures higher success rates on construction sites. Monitoring should be part of the project plan, as issues can often go unnoticed without regular checks.

What is Geotextile Tape and How is it Used in Construction? - Benefits and Limitations of Using Geotextile Tape in Construction

| Dimension | Description |

|---|---|

| Material Type | Polyester, Polypropylene |

| Width | Typically 2 to 12 inches |

| Thickness | Varies from 0.5 mm to 2 mm |

| Tensile Strength | Up to 2000 N/5cm |

| Color | Black, White, Beige |

| Applications | Soil stabilization, erosion control, drainage systems |

| Benefits | Durable, lightweight, easy to install |

| Limitations | Cost, potential UV degradation |

Related Posts

-

Top 10 Geotextile Gsm Types You Need to Know?

-

Maximizing Durability and Efficiency of Landscape Projects with Innovative Geotextile Use

-

Exploring the Environmental Benefits of Geotextile Mats in Modern Construction

-

Unlocking the Power of Geotextile Tape: 5 Key Benefits Backed by Industry Trends and Research Data

-

Exploring the Benefits of Woven Geofabric in Sustainable Construction Practices

-

Top 10 Geotextile GSM Options for Effective Soil Stabilization

-

Phone

-

E-mail

-

Whatsapp

-

Top