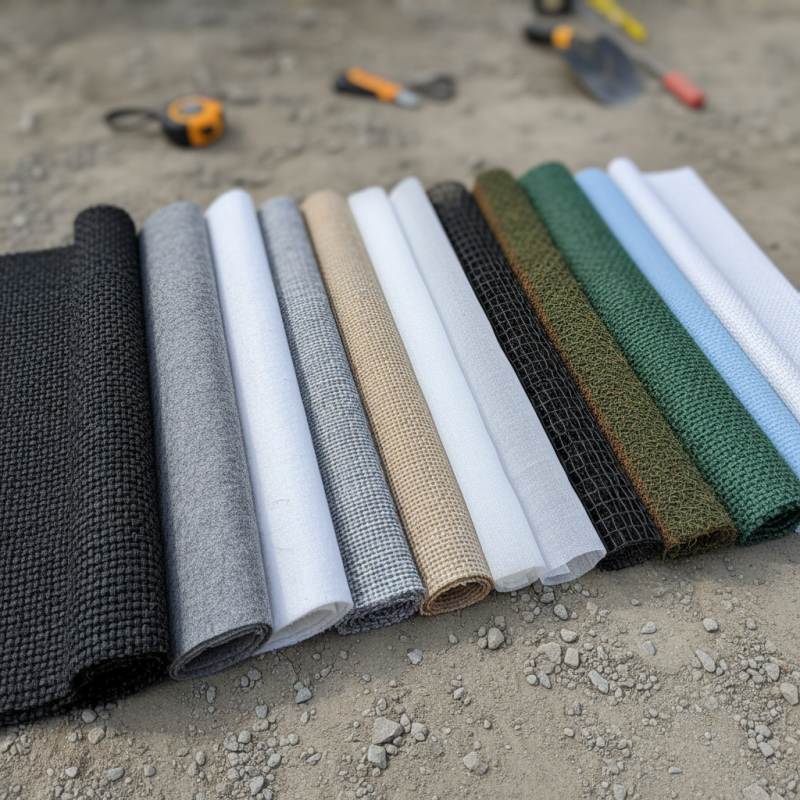

Top 10 Geotextile Gsm Types You Need to Know?

Understanding Geotextile Gsm types is essential for various construction projects. Geotextile materials play a crucial role in soil stabilization and erosion control. They are often used in road construction, drainage systems, and landscaping.

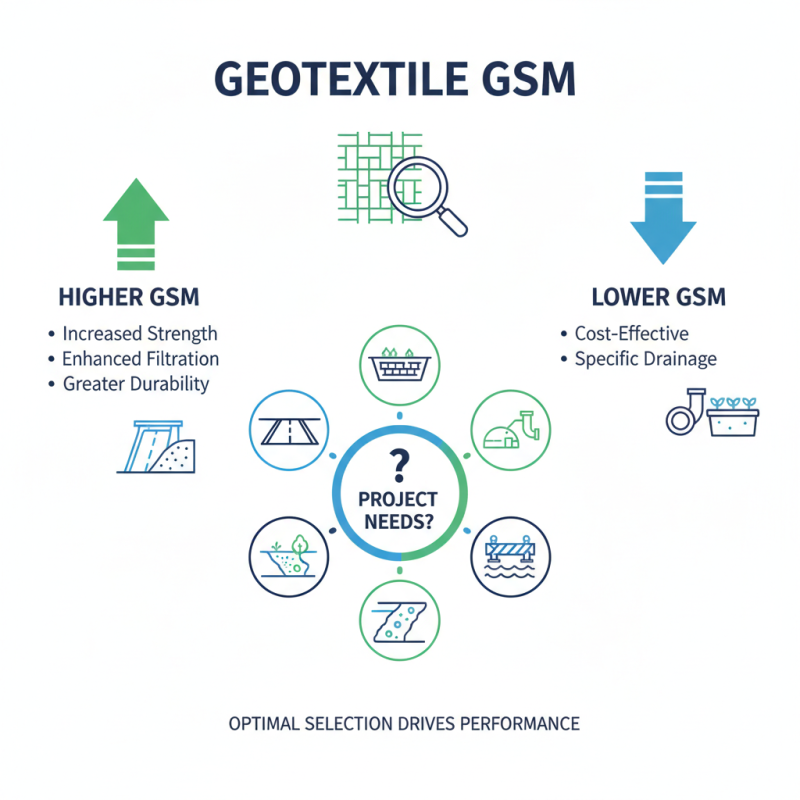

Geotextile GSM refers to the weight of the fabric. It is measured in grams per square meter. Different GSM types have unique properties. For example, high GSM geotextiles are robust and durable, making them suitable for heavy loads. On the other hand, low GSM fabrics are lightweight and ideal for filtration and separation purposes.

Choosing the right Geotextile GSM can be challenging. Misjudging the required GSM can lead to problems during installation. It's important to analyze project needs carefully. With a wide variety of geotextiles available, understanding their differences is key. This helps ensure that the right fabric is selected for each specific application.

What are Geotextiles and Their Importance in Civil Engineering?

Geotextiles are permeable fabrics used in civil engineering. They play a crucial role in soil stabilization, drainage, and erosion control. According to industry reports, the global geotextiles market is expected to reach $10 billion by 2025. This growth highlights their increasing importance in construction and environmental projects.

These materials are often used in road construction, landfill projects, and retaining walls. Geotextiles separate soil layers while allowing water flow, preventing soil erosion. Recent data shows that utilizing geotextiles can reduce construction costs by up to 30%. However, not all geotextiles perform equally. Choosing the right type based on specific project needs is critical.

Despite their advantages, challenges remain. Many engineers still overlook the selection criteria for geotextiles. Inadequate understanding can lead to project failures. In some cases, contractors underestimate the long-term performance of these materials. Awareness and education are essential for maximizing benefits.

Understanding GSM: The Key Metric for Geotextile Performance

Geotextile GSM, or grams per square meter, is vital for assessing performance. It directly impacts functionality in construction and environmental applications. High GSM fabrics often provide stronger filtration and durability. However, higher GSM isn't always better. The selection must align with project needs.

Data from industry reports reveals that geotextiles with 100-200 GSM are ideal for erosion control. These options balance strength and cost-effectiveness. Conversely, lighter geotextiles under 100 GSM may suffice for temporary projects. An understanding of GSM helps professionals select the right product for specific conditions.

A case study noted that a project chose a 150 GSM option, leading to failures due to inadequate support. This highlights the importance of thorough analysis. Selecting the right GSM is crucial and requires reflecting on specific project demands. Balancing weight, strength, and cost shapes the project's success.

Top 10 Geotextile GSM Types and Their Specific Applications

Geotextiles play a crucial role in various engineering and construction applications. Understanding the GSM (grams per square meter) of different geotextile types is essential. For instance, a geotextile with a GSM of 100-150 is commonly used for sediment control and erosion prevention. This lightweight material is suitable for temporary applications in landscaping and construction sites.

On the other hand, heavier geotextiles, with a GSM of 200-300, are preferred for reinforcement in road construction and geotechnical projects. These materials enhance soil stability and extend the lifespan of infrastructure. According to a 2022 industry report, the global geotextiles market was valued at approximately $5 billion, reflecting an increasing demand for durable and eco-friendly solutions.

While the benefits of geotextiles are evident, challenges in choosing the appropriate type remain. Some projects require a specific GSM for optimal performance, which may not be readily available. Additionally, improper installation can lead to failure, questioning the balance between cost and effectiveness. Proper research and testing are necessary to achieve the desired outcomes.

Top 10 Geotextile GSM Types and Their Specific Applications

Comparative Analysis of Geotextile GSM and Material Composition

Geotextiles play a vital role in civil engineering and construction. Their GSM (grams per square meter) rating is crucial for performance. The GSM influences the strength and longevity of the material. A higher GSM often means better durability. However, this doesn't always translate to better performance in all applications.

Different materials used in geotextiles have varying properties. For instance, polyester and polypropylene each offer unique strengths. Polyester is known for its resistance to UV rays and moisture. Polypropylene, on the other hand, is often lighter but may degrade faster under harsh sunlight. Understanding these differences is essential for selecting the right geotextile for your needs.

The choice of GSM must align with the project requirements. In some cases, a lower GSM could suffice. But for heavy-duty applications, a higher GSM is recommended. It's vital to assess environmental conditions and project specifications. Selecting a geotextile should be thoughtful and not rushed. Small details can lead to significant impacts. This area still requires more research and exploration.

Industry Standards and Testing Methods for Geotextile GSM Evaluation

When evaluating geotextile GSM, industry standards play a crucial role. GSM stands for grams per square meter. It is a measure of the weight and density of the fabric. The GSM can impact durability, strength, and filtration properties. Understanding GSM helps select the right geotextile for specific applications.

Testing methods are essential for assessing GSM. Common methods include weighing samples and calculating their area. The results should meet industry benchmarks. Advanced testing may involve assessing mechanical properties or permeability. It's important to follow the correct procedures to ensure accuracy. Often, variations in fabric production may lead to unexpected GSM results.

**Tips:** Pay close attention to the testing environment. Temperature and humidity can affect measurements. Always compare your results against established industry standards. If you notice discrepancies, consider re-evaluating your testing method. Ensure that you are using appropriate samples, as non-representative samples may yield misleading data.

Top 10 Geotextile Gsm Types You Need to Know

| GSM Type | Description | Application | Testing Method |

|---|---|---|---|

| GSM 50 | Lightweight and porous, ideal for filtration | Drainage and erosion control | ASTM D4779 |

| GSM 100 | Medium weight, good for separation | Base stabilization | ASTM D5199 |

| GSM 150 | Durable and resilient | Reinforcement in road construction | ASTM D6638 |

| GSM 200 | Heavyweight, high load-bearing | Engineering projects and landfills | ASTM D4595 |

| GSM 300 | Very high strength | Sustainable construction and heavy traffic areas | ASTM D6637 |

| GSM 400 | Ultra heavyweight | Severe erosion control | ASTM D6496 |

| GSM 500 | Super durable | Landfill caps and heavy structures | ASTM D751 |

| GSM 600 | Top-tier strength and durability | Extreme conditions in infrastructure | ASTM D7474 |

| GSM 700 | Maximum density and strength | High abuse applications | ASTM D6241 |

Related Posts

-

Maximizing Durability and Efficiency of Landscape Projects with Innovative Geotextile Use

-

Top 10 Geotextile GSM Options for Effective Soil Stabilization

-

Exploring Innovations in Gsm Geotextile at the 2025 China Import and Export Fair

-

Unlocking the Power of Geotextile Tape: 5 Key Benefits Backed by Industry Trends and Research Data

-

Exploring the Environmental Benefits of Geotextile Mats in Modern Construction

-

Exploring the Benefits of Woven Geofabric in Sustainable Construction Practices

-

Phone

-

E-mail

-

Whatsapp

-

Top